SAPONIFICATION PROCESS

JET SAPONIFICATION PLANT

The JET Saponification Plant requires a minimum steam consumption of about 100 kg/h each 1,000 kg/h of produced soap. The maintenance is simple and minimum. The JET has no moving mechanical parts; the pumps are the only moving parts of the process. The process is atmospheric. The plant is user-friendly and is easily controlled by a single operator. Easy visual access to all process points.

In the Full-Boiled processes the process water is abundantly used and remains into the soap. A typical concentration of full-boiled neat soap is 62% TFM and 33% water. A Semi-Boiled soap obtained with a conventional plant has a typical concentration of 58% TFM (glycerine excluded) and 30% water. The high content of water is necessary to facilitate the saponification and obtain a homogeneous soap mass. The JET Semi-Boiled saponification allows the production of neat soap at a very wide range of concentrations. It is possible to produce soap at 58% TFM as with a conventional plant and it is possible to produce:

- SEMI-CONCENTRATED SOAP – With a water content in the range of 20%, the soap can be just cooled down, without any evaporation, in order to obtain Laundry Soap or it can be processed by a Drying Plant with reduced Heat Exchanger and reduced Vacuum Section in order to evaporate a limited quantity of moisture and obtain Semi-boiled Toilet Soap.

- CONCENTRATED SOAP – With a water content from 16% down to 12% there is no further scope of drying and the soap is to be cooled down in order to obtain Semi-boiled Toilet Soap. A compact Chill-Roll plant is the ideal heat-exchanger to complete the process without the need of a more complex and consuming Drying Plant.

EMULSIFYING JET

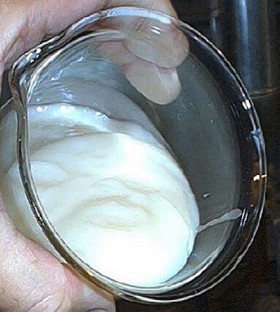

Simultaneously to the supply of the reagents, the JET receives a small flow of steam of which, flow and pressure, can be fine-tuned for the formation of the best emulsion.

Steam Injection has several functions:

- Provides the necessary kinetic power to generate a great emulsionated interphase.

- Triggers the saponificaton reaction providing the required thermal energy.

- Immediately increases the relative electrolytes percentage so as to allow sudden generation of enough quantity of soap necessary to keep a stable emulsion, whatever the level of free fatty acids might be.

CONTINUOUS SAPONIFICATION REACTOR

The Saponification Reactor is a relatively simple vessel consisting of three stages:

- THE RECEIVING STAGE - Here the JET releases the emulsion. It is completed with a rotating screw which facilitates the passage of the reacting mass to the second stage.

- THE REACTION STAGE – Here the reaction completes its linear phase. On the bottom of this second stage a pump allows the recycle of the soap from the bottom to the top; the same pump is used to empty the two first stages when required. The soap overflows to the third stage.

- THE COMPLETITION STAGE - Here the soap matures for a complete saponification. On bottom of such stage a pump delivers the soap to the downstream equipment or, when required, recycles it.

Thanks to its flexible design the described reactor can be also used as a batch plant, in such case the delivery pump is set to the recycle mode until the operator decides to download the soap.